High-Performance SMT Reflow Oven for PCB Assembly | Meraif

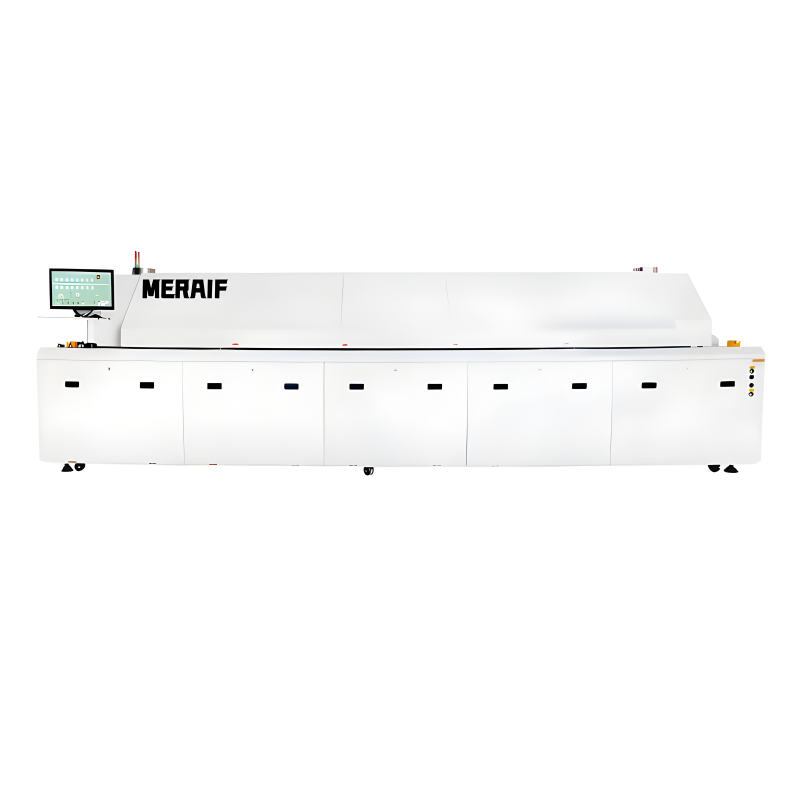

- Heating Zones: Multiple independent heating zones (e.g., 6, 8,10 or 12 zones) for precise thermal profiling.

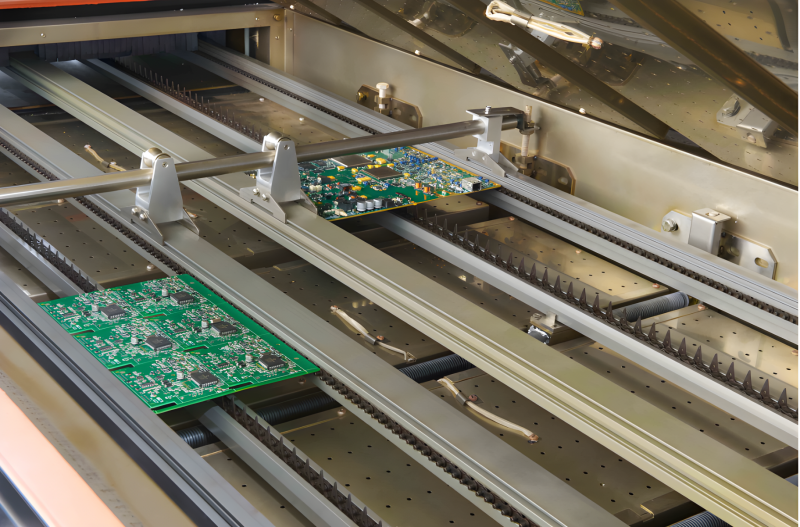

- Conveyor System: Adjustable conveyor speed for flexible production needs.

- Lead-Free Compatibility: Designed for RoHS-compliant production.

- Cooling Zones: Integrated cooling systems for rapid and controlled cooling post-soldering.

- Temperature Accuracy: ±1°C for uniform heating and reduced defects.

- Advanced Software: Real-time data monitoring and profile adjustments via intuitive software.

- Built-in Safety Features: Overheat protection, emergency stops, and efficient exhaust systems.

What is a SMT reflow oven?

An SMT reflow oven is a machine used in the Surface Mount Technology (SMT) process to solder components onto a printed circuit board (PCB). It uses controlled heat to melt the solder paste applied to the PCB, bonding the components to the board.

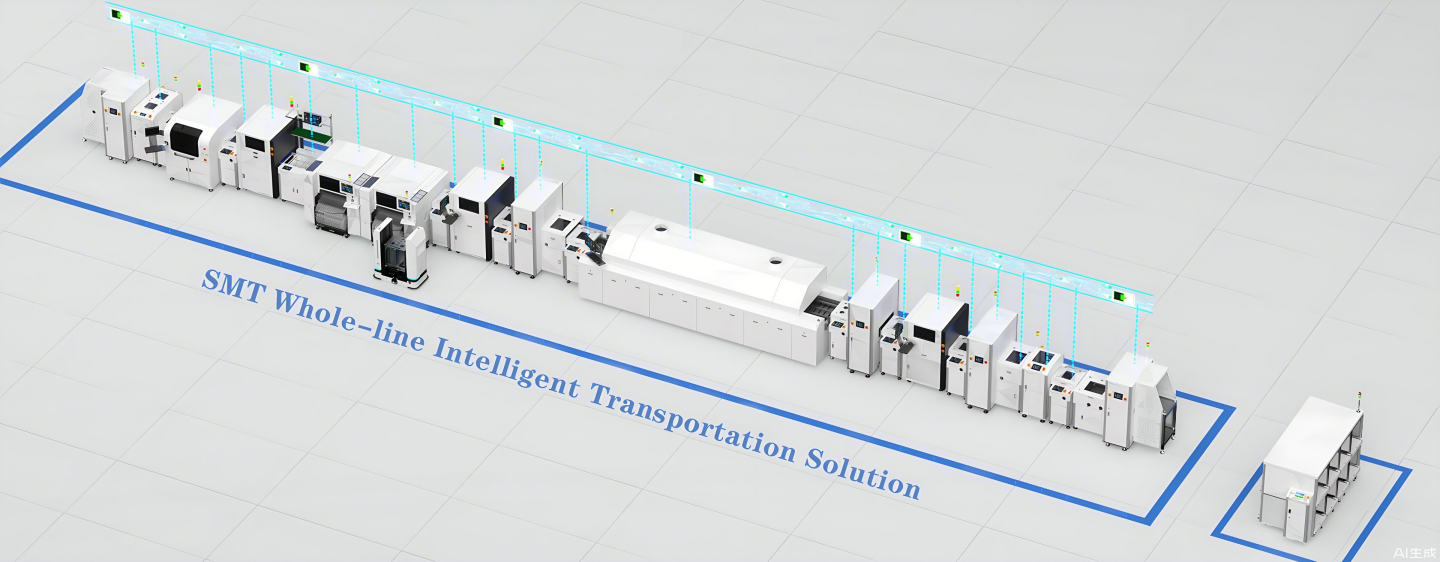

Types of SMT Reflow Oven – Choose the Right Reflow Soldering Solution

Reflow soldering ovens are essential for ensuring reliable and precise solder joints in PCB assembly. Depending on your production scale, component types, and application needs, there are various types of reflow ovens to choose from. Below, we’ll guide you through the most common types and their unique features to help you make an informed decision.

Features: Reduce oxidation, improve wettability, improve lead-free soldering, reduce defects

Applicable scenarios: lead-free soldering, high-precision PCB, medical equipment

Features: Eliminate voids, high welding strength, suitable for high-power equipment, low oxidation

Applicable scenarios: aerospace, LED modules, power electronics

What is the reflow temperature for SMT?

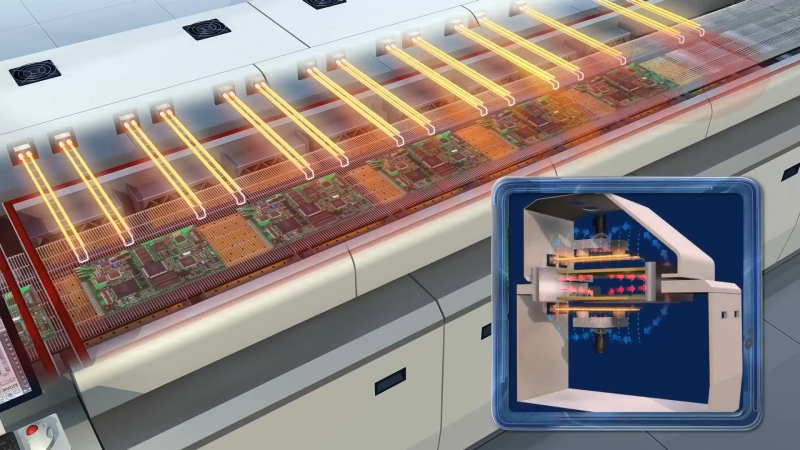

Preheat Zone: 150–180°C (302–356°F) – Gradual heating to prevent thermal shock and activate flux.

Soak Zone: 180–200°C (356–392°F) – Flux activation and preparation of solder paste for reflow.

Reflow Peak Temperature: 220–250°C (428–482°F) – The solder paste melts and forms strong bonds between components and the PCB.

Cooling Zone: Below 200°C (392°F) – Gradual cooling to solidify the solder joints.

What is the process of reflow oven?

Loading: The PCB with solder paste and components is loaded into the reflow oven.

Preheating: The oven gradually heats the PCB to a low temperature to avoid thermal shock and activate the flux in the solder paste.

Soaking: The PCB stays at a steady temperature to allow the flux to fully activate and prepare the solder for melting.

Reflow: The temperature is raised to the peak, where the solder paste melts, and the components are securely attached to the PCB.

Cooling: The PCB is cooled gradually, allowing the solder to solidify and form strong, reliable joints.

Unloading: The completed PCB is removed from the oven after cooling, ready for inspection or further processing.

Precision Manufacturing, On-Time Delivery – Choose Reliable SMT Reflow oven

When it comes to smt reflow oven, we’re more than just a supplier – we’re experts in precision manufacturing. With our in-house production facilities and CNC machining center, we ensure unmatched quality control and delivery reliability for every product.

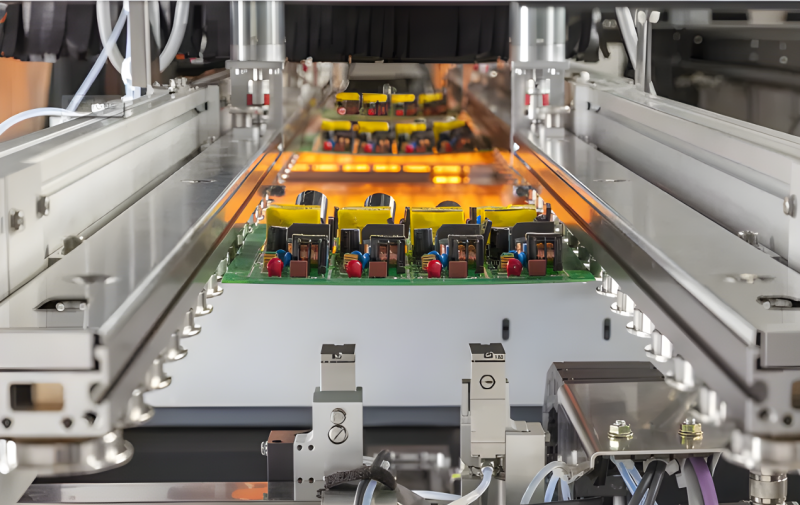

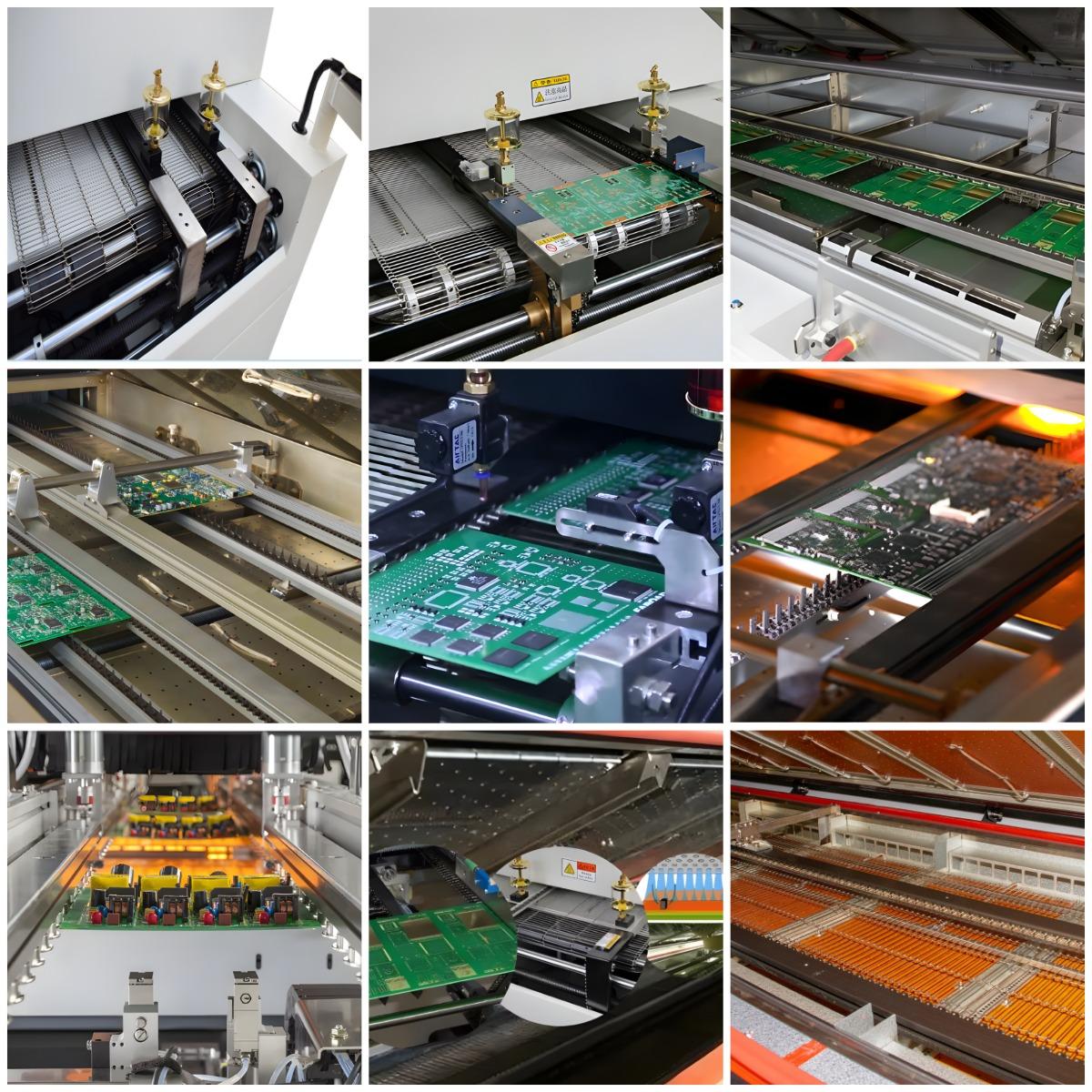

SMT reflow oven quality control

100% Quality Control

Every key component of our reflow soldering machines is meticulously crafted and inspected in-house, using state-of-the-art CNC precision machining. From heating modules to rail systems and outer casings, our commitment to excellence ensures outstanding stability and durability.On-Time Delivery, Guaranteed

Our in-house manufacturing allows us to streamline production processes and tightly manage lead times. Whether it’s a standard unit or a customized solution, we’re committed to delivering on schedule, keeping your production timeline on track.Flexible Customization Options

Thanks to our advanced CNC capabilities, we can adapt designs and specifications to meet your unique needs. We provide tailored reflow soldering solutions, ensuring your equipment is perfectly aligned with your production requirements.Expert Support Team

From R&D and production to factory testing, our skilled technical team provides comprehensive support to ensure seamless installation and efficient operation from day one.

Our Promise – Your Trusted Production Partner

- In-House Manufacturing: Total process control, visible quality.

- Core Component Production: CNC machining for high precision and long-lasting performance.

- Reliable Delivery: On-time, every time.

- Long-Term Support: Maintenance, upgrades, and technical guidance for sustained performance.

With our reflow soldering equipment, you’re not just getting a machine – you’re investing in a solution backed by rigorous quality management and reliable delivery.

Ready to enhance your production efficiency? Contact us today to learn more about our products and services ?

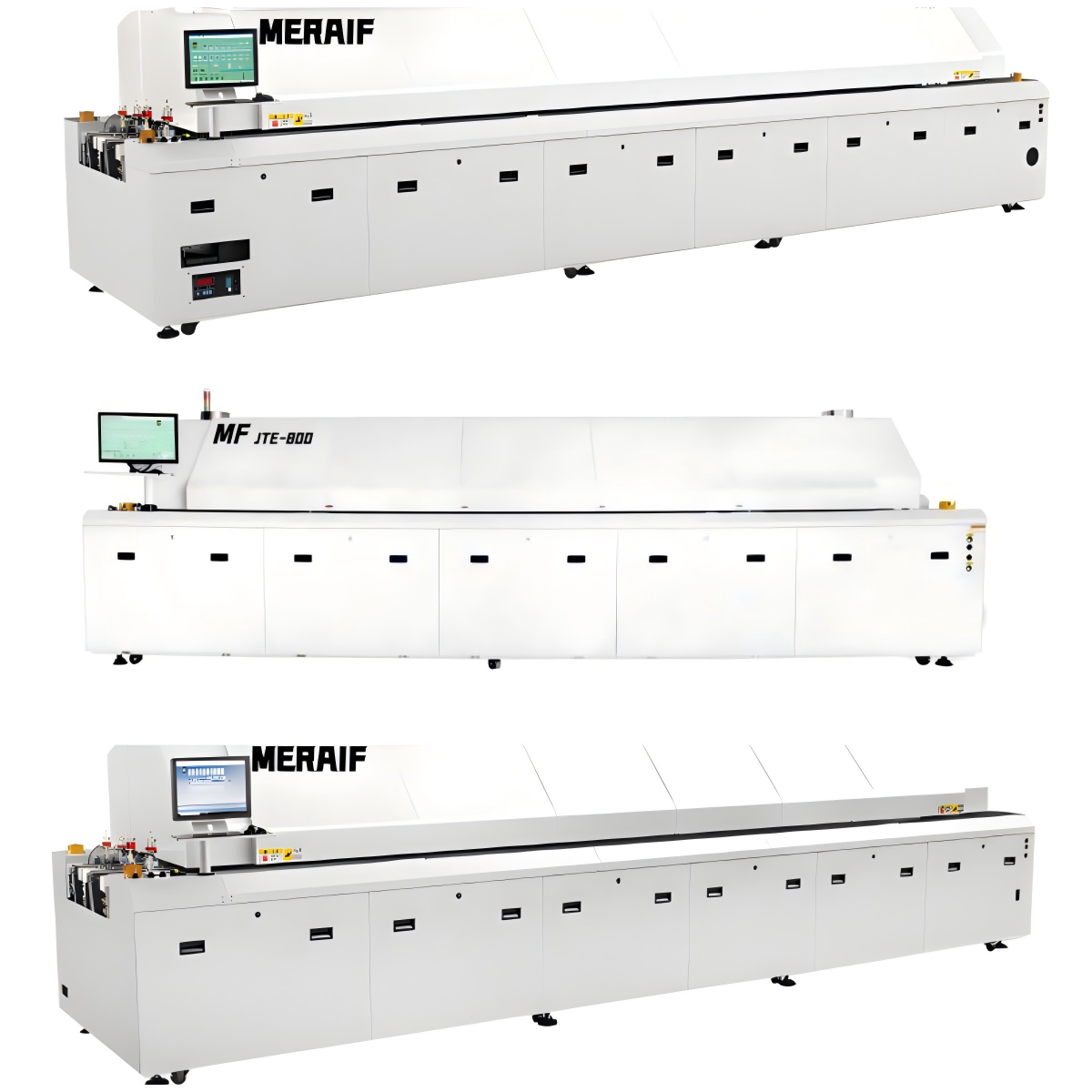

JTE Series - Reflow Oven (Dual Track)

Reinforced main boom; multi-layer insulation; high heat transfer efficiency; dual tracks; new cooling structure design

- Strengthen the main boom to ensure that the rails do not deform laterally, and prevent the occurrence of stuck or dropped boards.

- The furnace has multiple layers of insulation to minimize the impact of furnace temperature on ambient temperature.

- The improvement of heat transfer efficiency can easily cope with the requirements of more complex and larger lead-free processes for welding quality.

- The double rail structure effectively improves production efficiency, saves energy consumption and production costs.

- The new cooling structure design allows most of the exhaust gas to be filtered or recycled back into the furnace, reducing heat loss and making the flux recovery more thorough.

JTR Series - Reflow Oven (Nitrogen)

High capacity; Dual tracks; Cooling technology; Recovery system; Nitrogen control; Optional chiller; Optional oxygen content analyzer

-

High production capacity with a chain speed of 160cm/min, low energy consumption, and an advanced thermal management system to reduce costs. Designed for high-speed production and precise PCB packaging.

-

Dual-track speed change, single machine cost, double production capacity, energy saving up to 65%.

-

The latest cooling technology with multi-zone double-sided cooling, providing an effective cooling length of 1000mm to quickly reduce the product's outlet temperature.

-

The flux recovery system with multi-point collection improves efficiency and reduces maintenance time and frequency.

-

The nitrogen flow is controllable throughout the process, with each temperature zone independently controlled to maintain an oxygen concentration range of 300-1000ppm.

-

The new water cooling system and extended cooling zone enhance surface finish, reduce marks and internal stress, prevent deformation, accelerate shaping, and improve mass production efficiency. (Optional)

-

The instrument is designed for various gas environments, using an electrolyte diaphragm sensor and ARM embedded system for real-time oxygen concentration measurement in pure, inert, and special gases (acidic, alkaline, etc.). (Optional)

JTE Series - Reflow Oven

Guide rail system; heat balance; multi-layer insulation; recycling system; recyclable

-

The guide rail is specially hardened and durable;

-

The stainless steel double-row side chain is used, which is practical and reliable.

-

Theoretical design and actual testing, verified by customers, obtain the best repeatability result CPK value, and also allow many customers to see the lowest energy consumption on site.

-

The furnace has multiple layers of insulation and patented overflow collection design to minimize the impact of the furnace on the ambient temperature.

-

The rosin recovery system can be maintained online, with a fully modular design, convenient and fast maintenance, and reduced maintenance time and cost.

-

95% of the materials on the machine can be recycled.

V Series - Hot Air Online Vacuum Reflow Oven

Super strong vacuum; no temperature drop in vacuum zone; triple sensing technology; real-time monitoring of vacuum zone

-

Hot Air Online Vacuum Reflow Oven.

-

Super strong vacuum capacity can greatly reduce the void rate and improve the reliability of solder joints.

-

The vacuum chamber is three-dimensionally insulated and uses heating compensation to prevent temperature drop, which has higher welding quality and yield.

-

The front, middle and back triple sensing technology effectively prevents the plate from being pressed and stuck when the vacuum chamber is closed, making production smarter and more assured.

-

The vacuum area is no longer blind, and the temperature and vacuum degree can be monitored in real time. A special temperature tester can be optionally equipped to facilitate the adjustment of the temperature curve and maintain the stability of product welding.

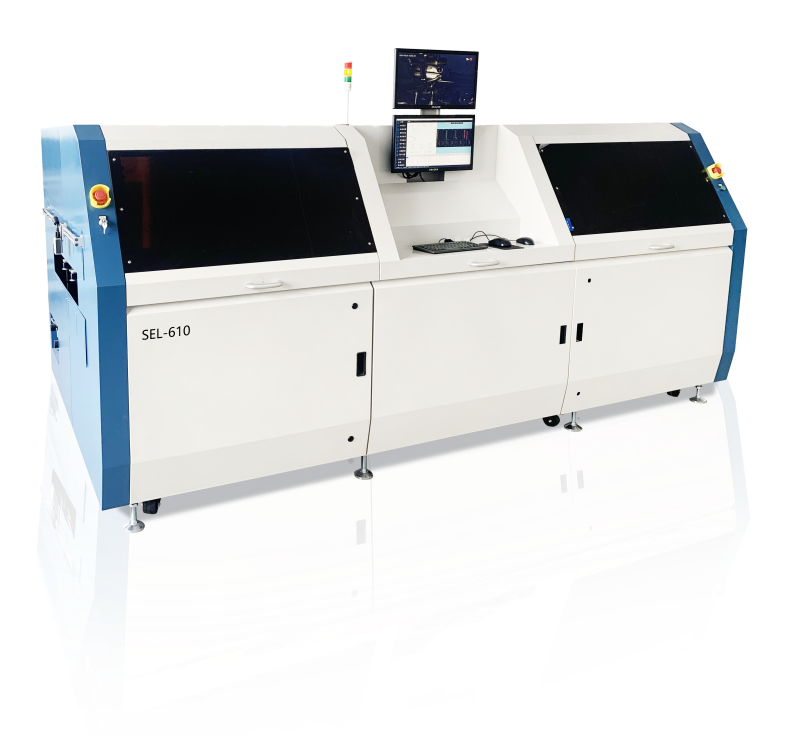

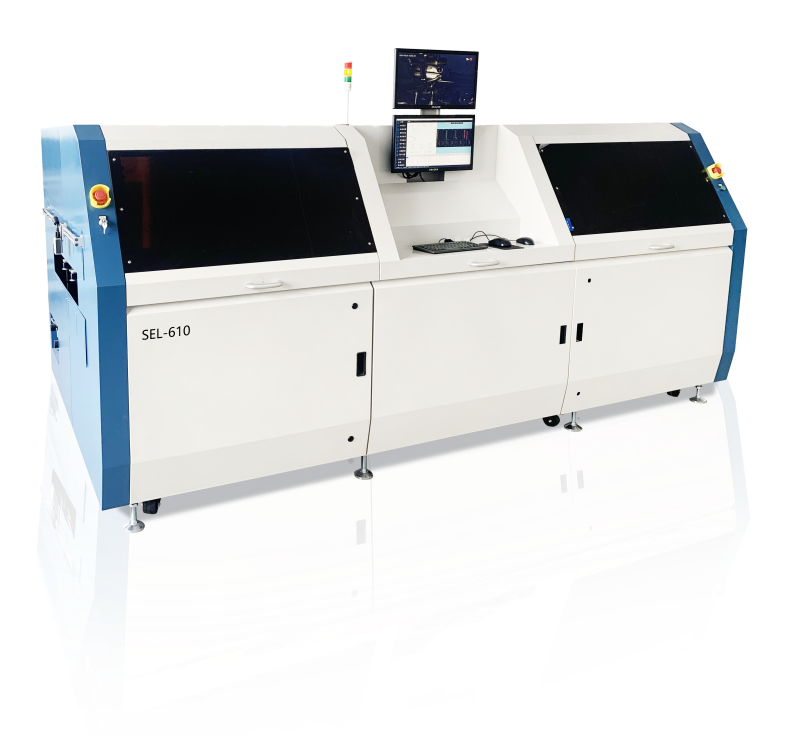

SEL series - online selective soldering machine

Integrated design; modular welding; high efficiency

-

Integrated design: spray + preheating + welding module, integrated design, flexible configuration, free expansion.

-

Welding modularization: spot welding module and group welding module can be freely selected and combined.

-

High efficiency: high efficiency is the key to selecting welding module.

-

Transmission structure: segmented module transmission structure.

Solve Your Reflow Soldering Challenges with Precision and Reliability

At Meraif, we understand the critical challenges you face when sourcing reflow soldering equipment. Whether you’re dealing with production delays, quality inconsistencies, high operational costs, or lack of technical support, our advanced reflow soldering machines are here to deliver exactly what you need.

Why Choose US?

At Meraif, we understand the critical challenges you face when sourcing reflow soldering equipment. Whether you’re dealing with production delays, quality inconsistencies, high operational costs, or lack of technical support, our advanced reflow soldering machines are here to deliver exactly what you need.

When it comes to soldering, precision is everything. Our reflow soldering machines are built with advanced CNC machining and undergo rigorous quality control to ensure consistent, high-quality soldering. Every component is designed for optimal heat distribution to prevent defects like voids, bridging, and cold solder joints.

- Precise Temperature Control: Multiple heating zones with accurate, uniform temperature control to ensure the highest soldering standards.

- Proven Performance: Tested for compatibility with a variety of components, including BGA, QFN, and fine-pitch components.

We know how costly production delays can be. With our in-house manufacturing and streamlined processes, we offer quick lead times to get your production back on track—on time, every time.

- Fast Shipping: We prioritize timely delivery to ensure your machines arrive when you need them.

- Quick Setup and Installation: Our team offers on-site installation and training, ensuring a smooth transition and immediate production uptime.

Reflow soldering doesn’t have to be costly. Our equipment is designed to be energy-efficient, helping you reduce your long-term operational costs without compromising on performance.

- Lower Energy Consumption: Eco-friendly design ensures low power usage, cutting down electricity costs.

- Long-Term Savings: With high-quality components and durable construction, you’ll benefit from reduced maintenance costs and extended machine lifespan.

Every factory is different, and so are your soldering requirements. Our team works closely with you to customize the reflow soldering solution that best fits your production environment, PCB types, and component sizes.

- Tailored Solutions: From component-specific designs to size adjustments, we deliver machines that meet your exact needs.

- Flexible Adaptability: Our equipment can easily be upgraded as your production requirements evolve.

When you choose Meraif, you’re not just buying equipment—you’re gaining a partner for the long run. Our comprehensive after-sales services ensure that your equipment stays in top condition throughout its lifecycle.

- Dedicated Technical Support: Our expert team is available to assist with any issues, offering quick resolutions to minimize downtime.

- Training and Maintenance: We provide hands-on training and ongoing maintenance support to ensure your operators are fully equipped to use the machine efficiently.

Resolve Your Reflow Soldering Pain Points Today!

Don’t let delays, quality issues, or high maintenance costs affect your operations. Our reflow soldering machines are designed to boost efficiency and solve these problems.

Contact us for a customized quote. Our team will help you find the ideal solution to improve soldering quality and reduce downtime.

Request a Quote Now

Speak to an SMT expert: Have questions? Our team is ready for a personalized consultation.