- Building 6, Section 2, Yingshui Villa, Longhua District, Shenzhen, Guangdong

- +8613424013606

- info@meraif.com

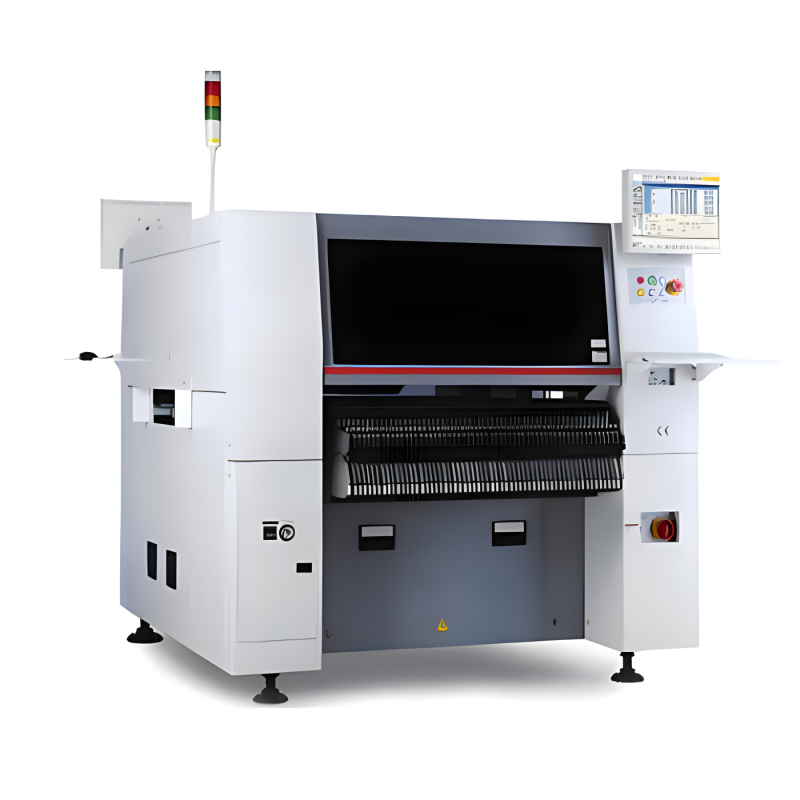

High-Precision, Scalable, and Cost-Effective Solutions for Your PCB Assembly Needs

High-Speed: Maximize throughput with minimal downtime.

Precision: Ensure perfect solder joints with our cutting-edge technology.

Flexibility: Adapt to various component types and PCB sizes.

Customizable: Tailor the line to your unique production needs.

We offer one-stop SMT production line solutions to boost capacity, ensure quality, and reduce manual effort and costs.

Our SMT production line offers complete equipment, from placement to reflow machines, enhancing efficiency, ensuring quality, and reducing costs. It supports both large-scale and small-batch production with various component types and PCB sizes.

Tailored Solutions: Custom SMT lines to suit your production needs.

Cost-Effective Options: New and refurbished machines for every budget.

Expert Consultation: Personalized advice to optimize your SMT setup.

We offer a full range of SMT equipment from world-renowned brands, including but not limited to: Hanhan (Samsung), Yamaha (Ipulse), Fuji, Juki, Panasonic And So On.

We not only provide SMT machines, but also complete SMT production line equipment, such as:

Solder paste printer, reflow machine, automatic board separator, AOI/3D SPI inspection equipment, PCB cleaning machine, SMT machine supporting system (PCB handling system, material storage system, etc.)

Speed : 92,000 CPH

Placement speed: 12,000 CPH (Optimum)

Placement Speed 47,000 CPH (Optimum)

Placement Speed:30000CPH(Optimum)

Placement speed :42,000CPH Optimum 29,000CPH IPC9850

Placement speed : 75,000 CPH supports dual-track

Placement speed(Optimum):100,000CPH

Placement Speed: 95000CPH.

Placement Speed: 80000CPH.

Placement Speed: 200,000 CPH

Placement Speed:46000CPH

Placement Speed RH2:41,000 cph

Placement Speed RH2:46,000 cph

Placement Speed H08N:13000cph

Placement Speed H12HS: 22,500

Placement Speed:Max.speed*5:51500cph(0.069s/chip)

Placement Speed:Up to 77,000 CPH

Placement Speed:Max. speed 46 000 cph (0.078 s/ chip)

Placement Speed :PC size 18 000 cph (0.20 s/chip)

As a motherboard manufacturer, you know that increasing efficiency, ensuring quality, and adapting to market demands are key challenges. Our SMT line, designed for motherboard production, offers advanced technology to enhance automation, boost capacity, reduce costs, and meet tight deadlines, giving you a competitive edge.

Customer Feedback:

“Since using your SMT line, our efficiency has risen 40%, especially in production cycles and quality control. The equipment is reliable, and after-sales service has been excellent. We’ve seen a significant drop in costs and a boost in output.”

— Motherboard Manufacturer

Our SMT equipment offers high-speed placement and precise alignment, ensuring accurate placement of all components, including micro and ultra-micro parts. With advanced vision inspection and real-time feedback, it guarantees perfect production. Faster cycles increase output and boost capacity.

Our fully automated SMT production line reduces human intervention, minimizing errors and labor costs. Automation enhances efficiency, stability, reliability, and reduces operational expenses.

Our flexible SMT production line adapts to both small-batch and high-volume production. With a modular design, it easily adjusts to varying order requirements, ensuring high efficiency and quality in all production scenarios.

Our SMT equipment features an intelligent visual inspection system that detects placement accuracy, component orientation, and quality issues in real-time. This ensures strict quality standards, reduces defects, and minimizes rework, crucial for precise motherboard manufacturing.

Choosing our SMT production line means a reliable partner for success. We offer full technical support, from installation to after-sales service, and routine maintenance to keep your equipment running smoothly and minimize downtime.

We provide tailor-made SMT production line solutions for various production needs. Whether it is large-scale production or small-batch customization, we can provide suitable equipment configuration and workflow design according to customer needs.

Professional consulting services: Our team of engineers provides you with technical evaluation and product recommendations to ensure that the equipment you choose can best match your production needs.

Technical support and training:Provide equipment installation, commissioning and training services to ensure that the equipment can operate efficiently and the operators can master the use of the equipment.

Our technical support team provides 24/7 online help to answer your technical questions at any time.

Through actual customer cases and specific application scenarios, we demonstrated how our SMT equipment can effectively solve industry pain points, improve production efficiency, and adapt to application needs in various fields.

Our SMT equipment is key in producing smartphones, tablets, wearables, and other consumer electronics.

while meeting the stringent standards of the automotive industry.

Our SMT equipment ensures precise assembly and component installation for medical devices, meeting strict quality standards.

With advanced detection systems, it enhances reliability, reduces errors,

and ensures compliance with the industry’s toughest certifications and regulations.

When faced with high production costs and efficiency issues, a well-known smartphone manufacturer chose to work with us and customized an SMT production line to assemble mobile phone components. After implementation, they achieved significant production efficiency improvements:

“By using the SMT production line provided by your company, our production capacity has been significantly improved. The automated system reduces labor costs and shortens production cycles, allowing us to respond to rapid changes in market demand.”

An automotive electronics company specializes in the production of in-vehicle sensors and navigation systems, but they were faced with the problem of insufficient precision in the placement of precision components, which affected the reliability of their products. By optimizing the configuration of our SMT placement machines, they successfully solved this problem:

“By optimizing the configuration of the placement machine, we have significantly improved the accuracy and production efficiency, which has greatly improved the quality stability of automotive electronic products. Our customers are very satisfied with the reliability of the product.”

Tailor-made solutions for each industry: We know that each industry has unique needs, and our equipment is highly flexible and customizable to meet the special requirements of industries such as consumer electronics, automotive electronics and medical devices.

Improve production efficiency: Our SMT equipment significantly improves production efficiency through a fully automated system, reduces manual operations and human errors, and ensures fast, efficient and low error rates in production.

Reliability and quality assurance: The equipment is equipped with an intelligent detection system to ensure that the product meets the highest industry standards, especially for industries such as automotive and medical devices that have extremely high requirements for reliability and precision.

Our high-performance SMT machines offer precision placement, reliable soldering, and customized solutions to boost efficiency and reduce downtime.

For assistance, email us at info@meraif.com.